Hey guys and girls bare with me on this one as I'll explain it in depth so you understand what I'm planning to do. I'm not a rod builder, period. An avid fisherman yep but by no means a rod builder so if I offend anyone with what I want to do to this rod I apologize in advance. Where I fish there is a lot of dead trees, a lot, and I fish from a small kayak and am literally bumping off trees it gets that tight. So tight it's impossible in many instances to get a cast in with my 6 ft rod. I bought a small kids 4ft spin rod for $10 and chucked a baitcaster reel on it as that's my reel style of choice, yes not the right thing to do but I just wanted to get the feel of and see if using such a short rod was going to be feasible, to my surprise I was still getting a good distance with casting light lures and was able to get many more casts in where if i was using the 6ft rod I would be whipping the tree trunks around me. I have rang around, looked online searches high and low and can not find a 4ft baitcaster rod (in Australia), I can get one custom made but I do not want to spend that amount of money and I don't have the gear to build a rod myself, nor do I really want to attempt such a task, which leads me to what I want to do and get some opinions on.

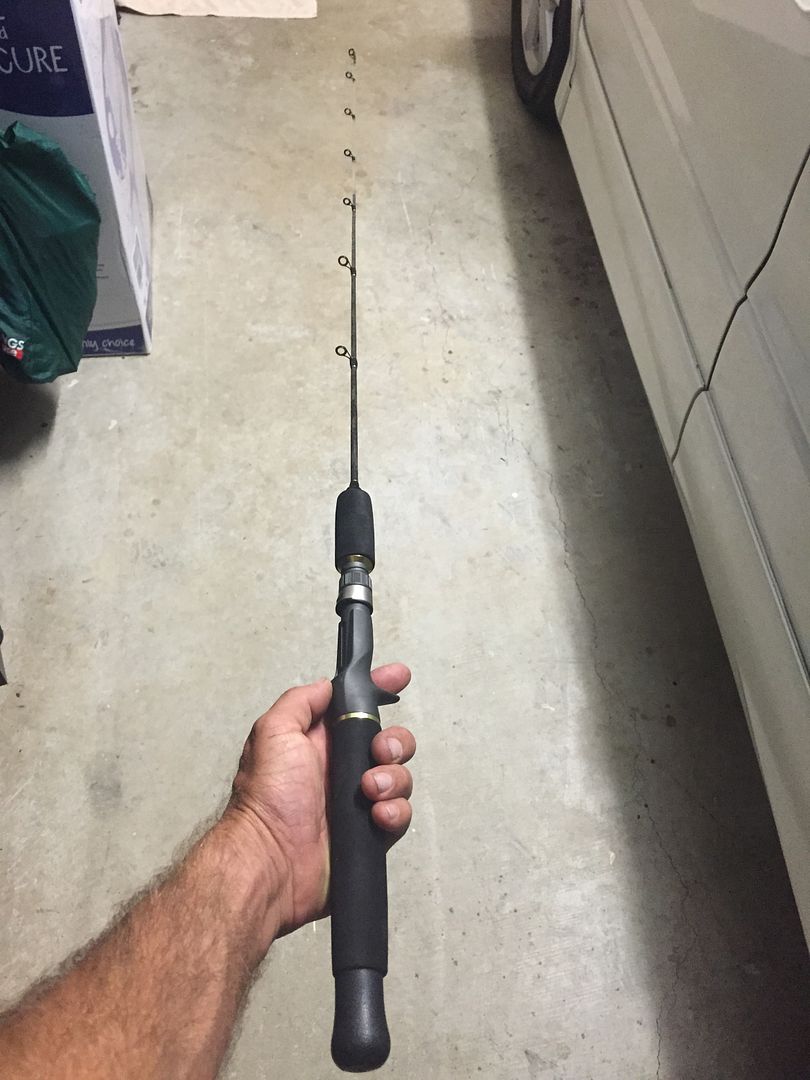

I have found a decent graphite 5'4" baitcaster rod off the shelf for a very reasonable price, and have the idea of cutting it down to the size I want it to be. (4ft overall) I understand rods are built via sliding handles and reel seats etc from the tip down, but to save dismantling the entire rod just to take a foot and a half off the butt section would still be quite expensive to do.

I was thinking what I could do is, is cut the rod just above the fore grip, then cut say another 20-30mm off of the bottom of the top half so that it reduces the diameter enough so I can slide the top half down inside the blank of the lower half. I would plug the cut end of the top half with some epoxy. Inject epoxy down into the blank that has the handle and reel seat on it, then after removing any guides I need to off the top half, push the top half down inside the lower half with the idea that because I have plugged the bottom of the top section of the rod, when I push the top section into the lower section, if I have filled it with enough epoxy it will completely surround and bond the two together with any excess being forced out the top and cleaned away.

This way I can just reuse the handles and reel seat with as little fuss as possible. I know it will be a bit of a challenge to get it completely straight but for what I'm using it for it doesn't matter if it's a little off centre, however I will some splint it, to keep it as straight as possible whilst it all cures. I hope that all makes sense.

It's a bit of a butchers approach I know, but for me would be the most cost effective and easiest way to get the rod I need, if it works. I'm going to give it a go, but am just after any ideas or tips that might make the process any easier, i.e the correct epoxy to use, how to make where the top half slides into the bottom half look neat, how to finish it off etc.

This rod is only going to be used when I can't get a cast in with my 6 ft and does not need to be perfectly balanced, just functional and look semi decent in finish. The rod specs are to be about 1-3kg so I am not fishing for marlin, I am only chasing bass and Saratoga in Australia.

Thanks to whoever reads this and I look forward to any feedback. Cheers

Reply With Quote

Reply With Quote