Hey Guys

This is a work in progress. So this will change after a while, Longer term it will only be a link.

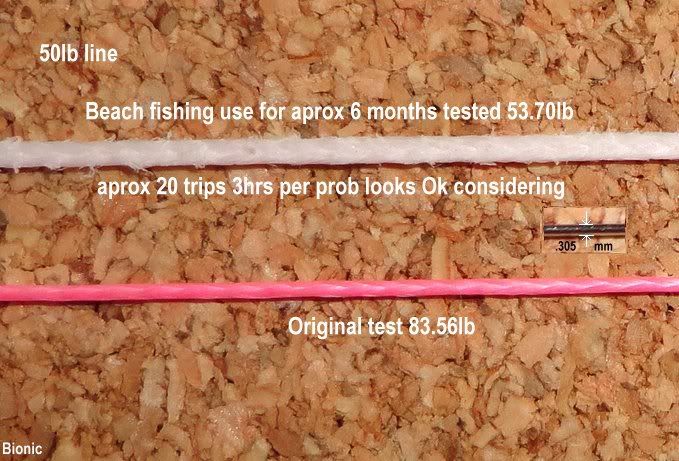

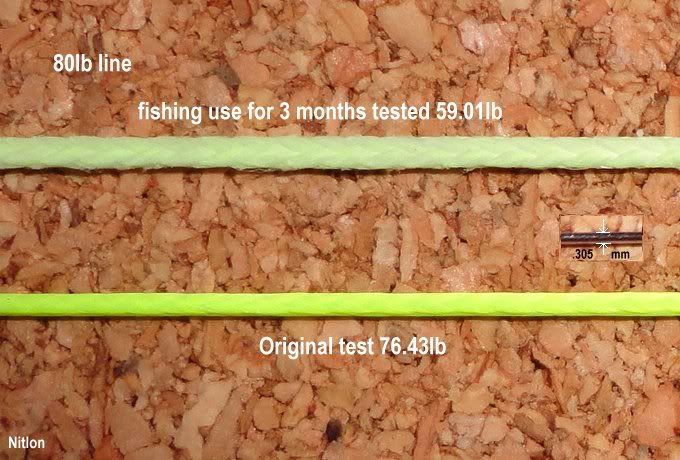

I did some braid strength tests some time back, then had the same lines sent back in for retesting after some use, just to see how strong they still were.

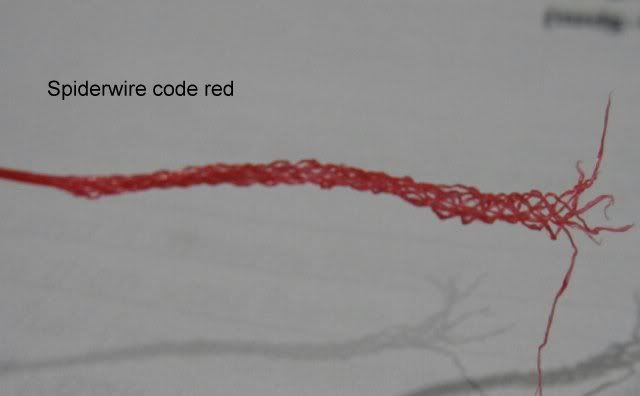

I was surprised to see not only the damage to the braid, the slight increase in size, but the reduction in line strength of up to 45% in some cases.

Some lines / brands reducing in strength more than others

I read a lot in these posts about lost fish and unexpected line breakages, for what seems no apparent reason, well maybe a reason lies within here.

Another thing comes to mind, removing so called wind knots and tangles, I see that an idea is to slobber all over the line and pull each end and the knot comes out, and at the same time you most likely just lost 10% of the lines strength. Or a little rubbing on the line on the spool by some thing while traveling, then wonder why it broke for no reason???

So, to the Guys that are setting reel drags, to the results of tested breaking strains, lines tested to breaking point, you may need to reconsider the level you are running to, well take 22% off the top if the line has had a few outings, in a few instances a lot more.

So it brings me here.

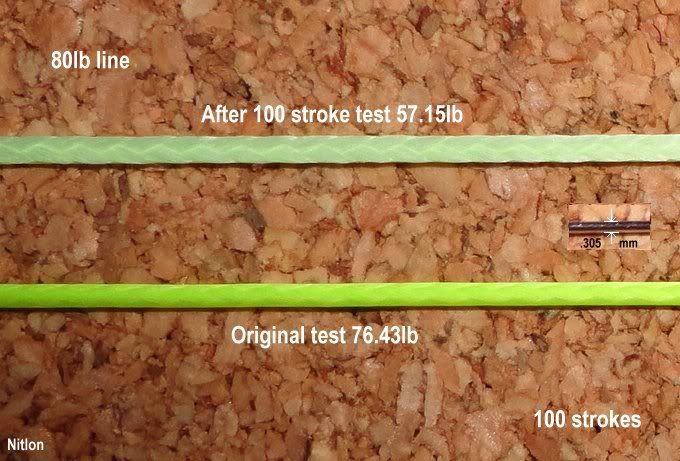

I spent an incredible amount of time trying to artificially duplicate the wear results, maybe even to try to pre-age the line so its similar to usage, UV exposure is not included in the tests, although may play a part.

Set up, I made a jig set up with 3 new Shimano eyelets (these have a flattish section on the inside) do not use any other eyelets or it will not work. The 2 lower eyelets are set opposite each other at 55 deg off horizontal, jig weight 510 gram in water 458gram, (not all of the jig is in water). See Jig photo.

The wear / age process.

The line is passed through the eyelets with each end of the line held on rods, the jig is lowered into the water covering the 2 lower eyelets, movement of the line is, one end up and the other down, the process does not try to lift the jig up off the bottom, but does move it about.

Every 10 strokes the whole of the line is turned 180 deg, left to the left and right to the right, no twists in the line, total strokes 100, that is 50 up on the left and 50 up on the right. That 100 strokes is a total of 50 cycles. Each stroke is 400mm long.

I know that more and differing types of loads and twists are on lines, but this a simple procedure and can be easily done.

Photos.

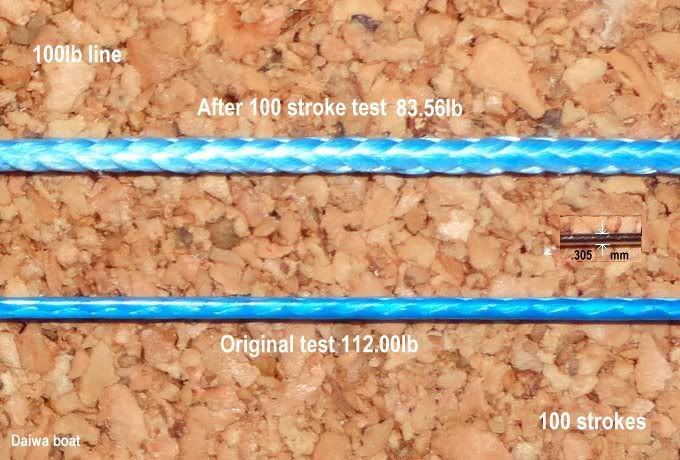

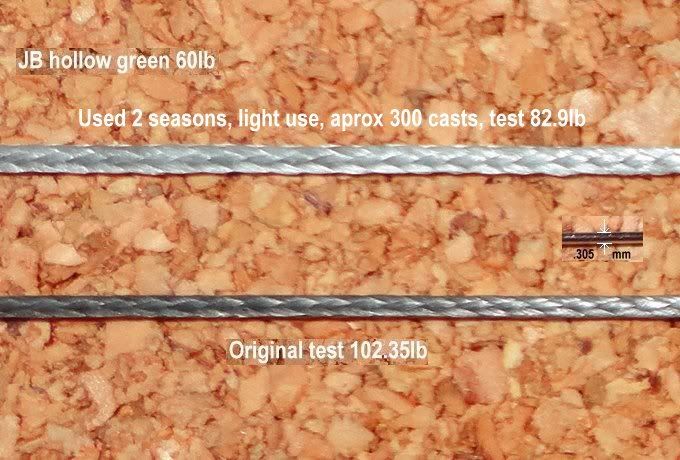

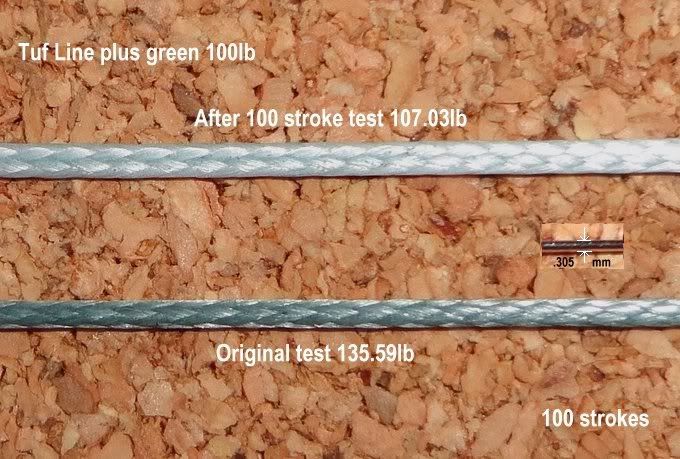

The shots were set up so they are all the same and line sizes can be compared.

A jig is the used to hold the camera at the same height and position, a 0.305mm marker is shown, to show size relevance.

I know that you will never accurately duplicate line use, far too many variables, BUT if it looks worn, faded and its size has increased, its time to renew it, or at least remove some.

I started here.

Photo 1, Used and new.

Photo 2, Used and new.

When they start low they wind up even lower.

These are the lines that were put through the wear / age process.

1 and 2 are the same lines as 1 and 2 above photos.

The following lines are lines i had as retained samples.

Used sample below.

New sample 100 strokes below.

Hollow lines below

This is a new line that was sent in for testing by GDC23 some time back.

This is the same line after a little use, off the same spool thanks GDC23. The line looked good, but its not a 100lb line as the ABS initially indicated.

When you think about wear of the braid, you think about line in and out of the water, then back and forth along the runners, line tearing through the water, strain on and off the line, winding up on the spool criss crossing itself, line tight around and rubbing on the anti twist roller, with a little luck fish thrashing about, but having seen this photo it's an added wearing action.

Having a manufacturer under state the strength of the braid may be an advantage with this, as you can see that 22% of the strength and beyond can be lost, for those that use line where the actual strength is below or at the stated strength, then loosing 22%+ can be an issue, especially as some can loose 45% strength,,,, That's based on the samples, method and the tests that I have done.

I had a Used line sent in, a sample off the used end and a sample from the inner most section on the spool.

Inner unused section tested at 101.9lb the used section 84.8lb. A plait sent in with the line to form a double failed at 76.2lb.

Which brings another twist into all this, the knotability of a used line, and that is another story.

So,,, That ABS does not hang about for long. and makes some of the numbers that get bandied about seem short term.

Paulus Just Fishing

Paulus

Paulus Just Fishing

Reply With Quote

Reply With Quote