-

Ausfish Bronze Member

penn squidder 140/145/146 rebuild

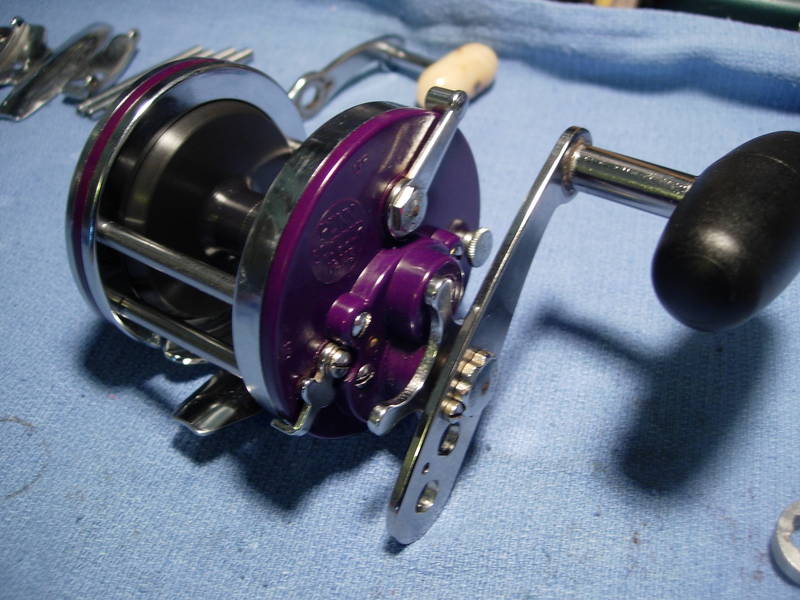

here's another old standard from penn. the squidders continue to remain popular among long distance surf casters. they also performs well for many inshore light tackle applications. a single screw also allows you to remove the side plate and easily clean the reel or change spools.

first, go to pennparts.com for the schematics and parts lists. for this particular rebuild post, i will be working off the 145 schematic.

140L - http://store.scottsbt.com/category1....9&ClearCache=1

140L-LH - http://store.scottsbt.com/category1....0&ClearCache=1

145 - http://store.scottsbt.com/category1....1&ClearCache=1

146 - http://store.scottsbt.com/category1....2&ClearCache=1

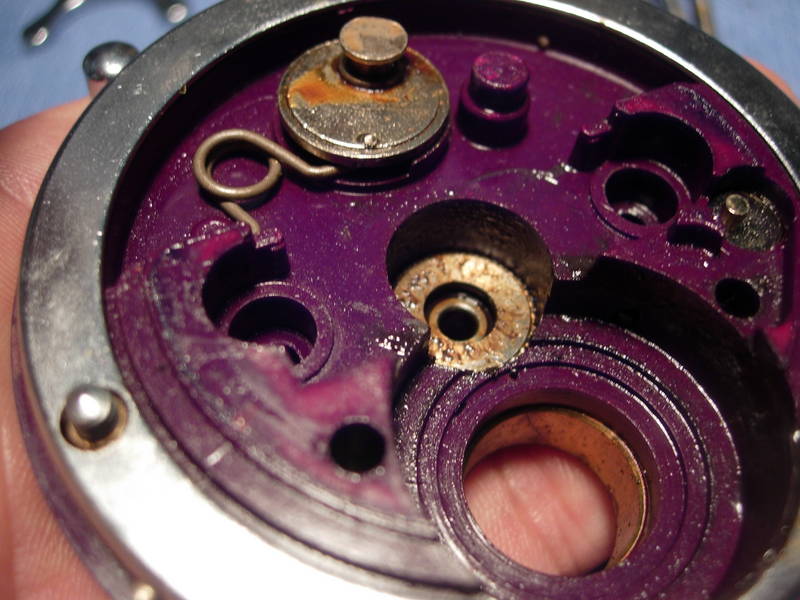

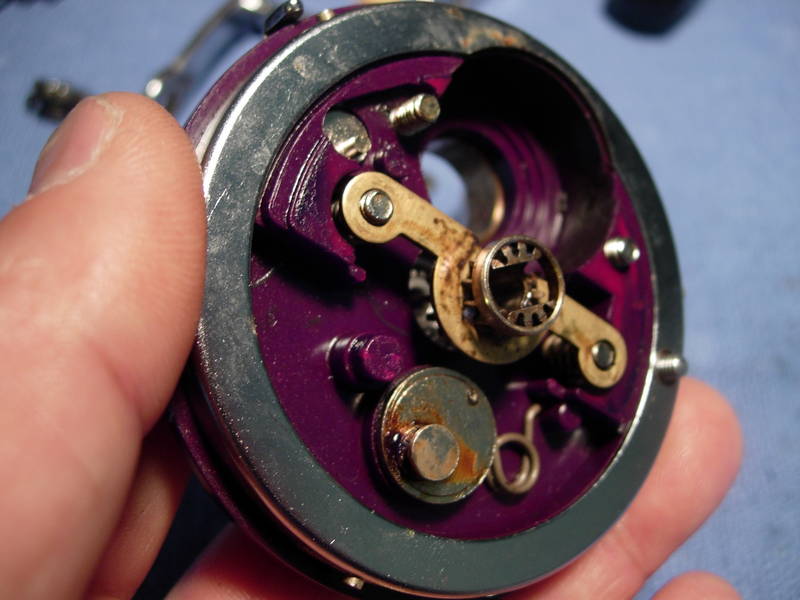

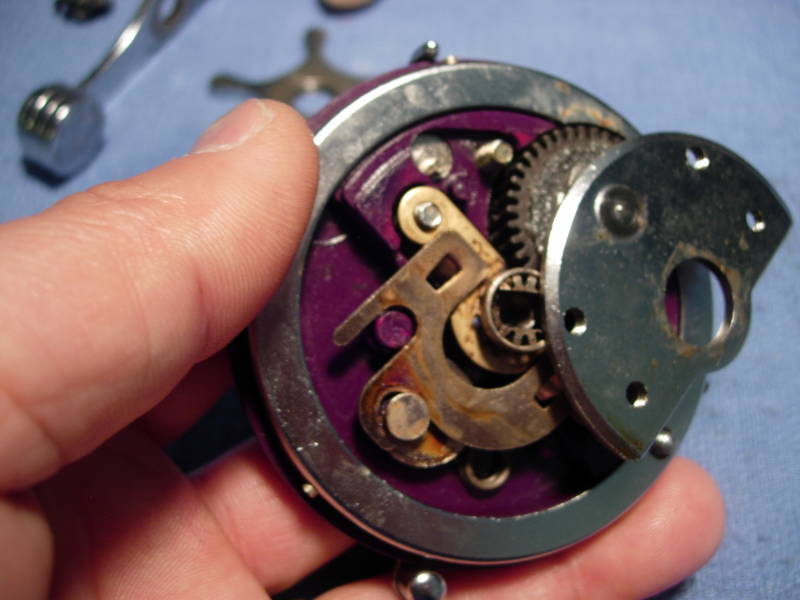

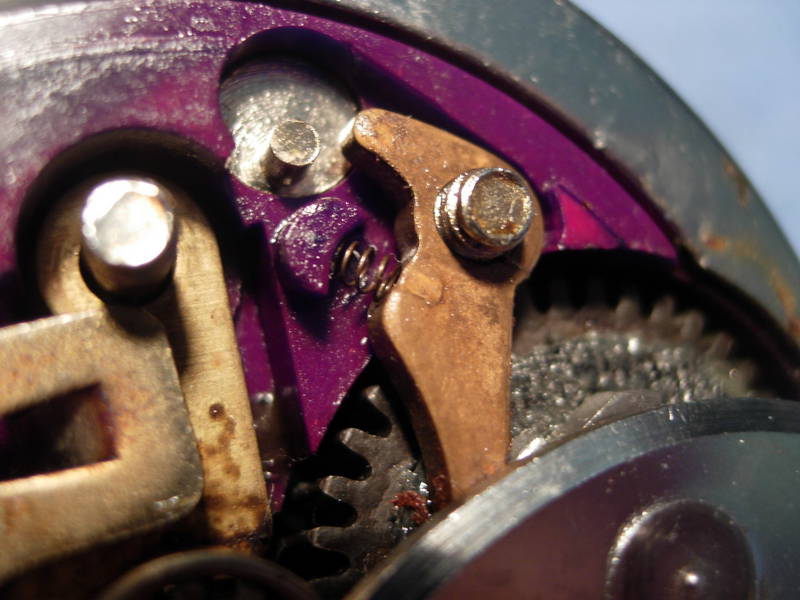

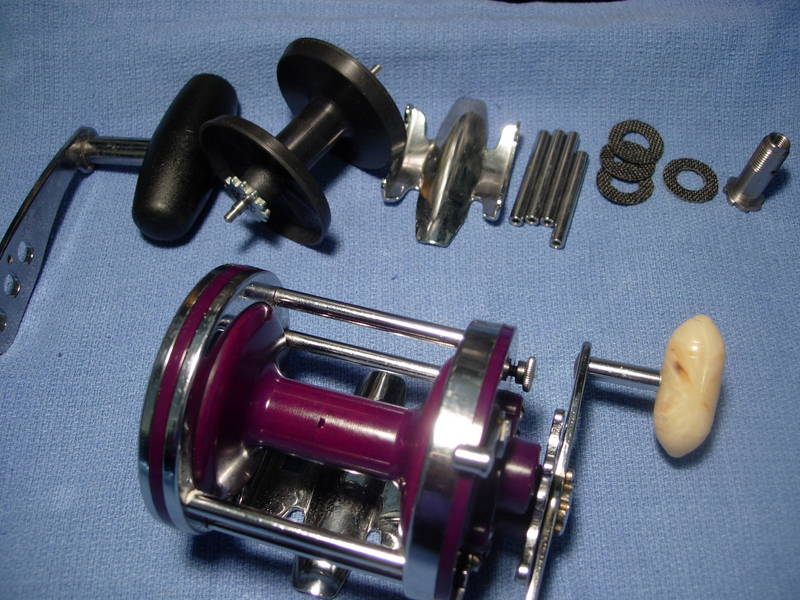

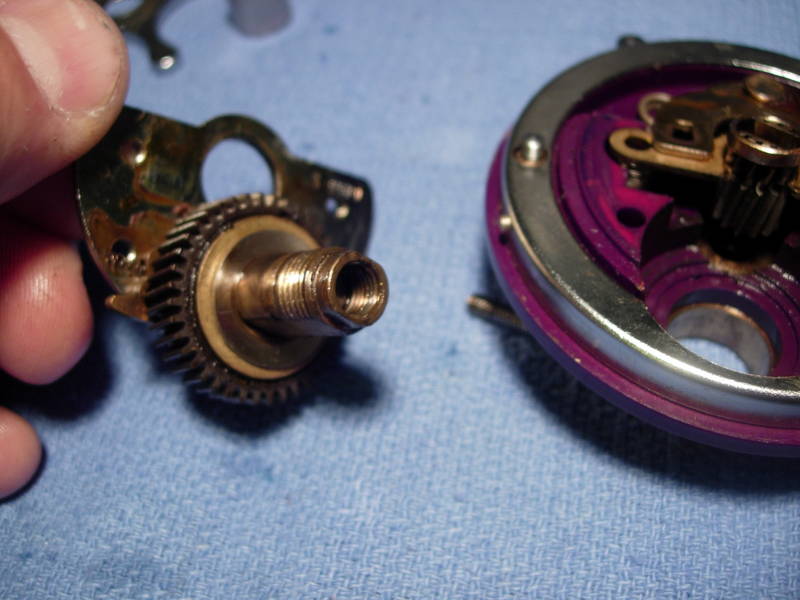

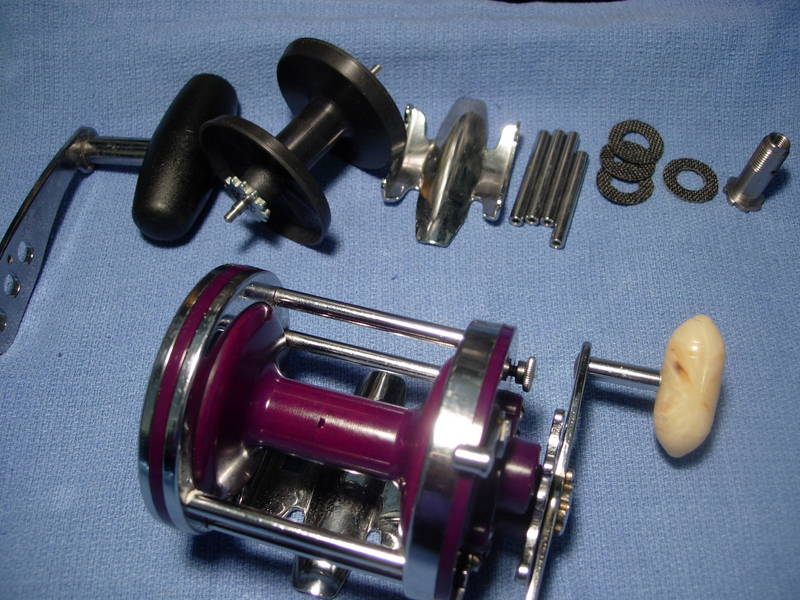

what we're going to do with this reel is to hotrod it a little, with a jigmaster power handle (#24-56), a narrow frame and spool conversion kit http://store.scottsbt.com/KIT140-146...13263C202.aspx, a new set of three #6-60 drag washers inside the main gear, a new #6-113 drag washer under the main gear, and a stainless steel gear sleeve that was made up custom for me. please note that this is not the same #98-60AT or #98-505AT stainless steel gear sleeve carried by pennparts.com. this was a limited run made by pete kolekar at my request. there are only a few left.

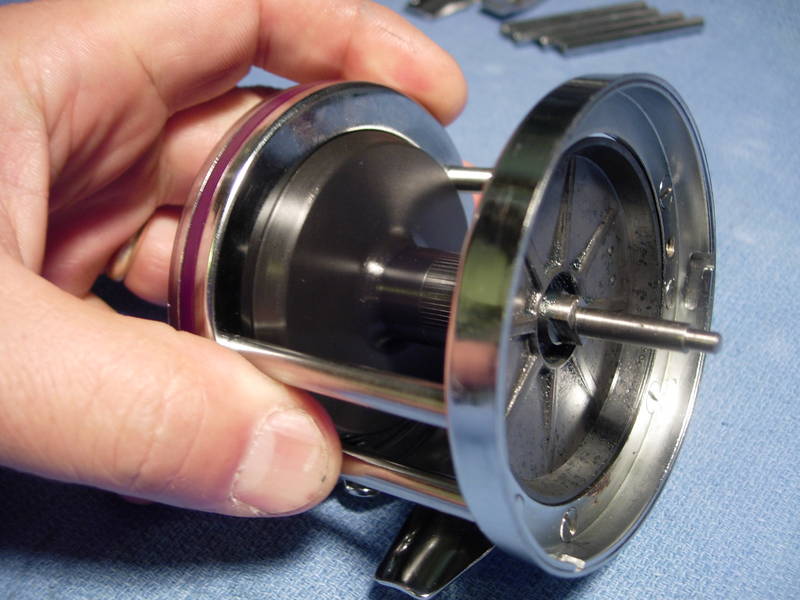

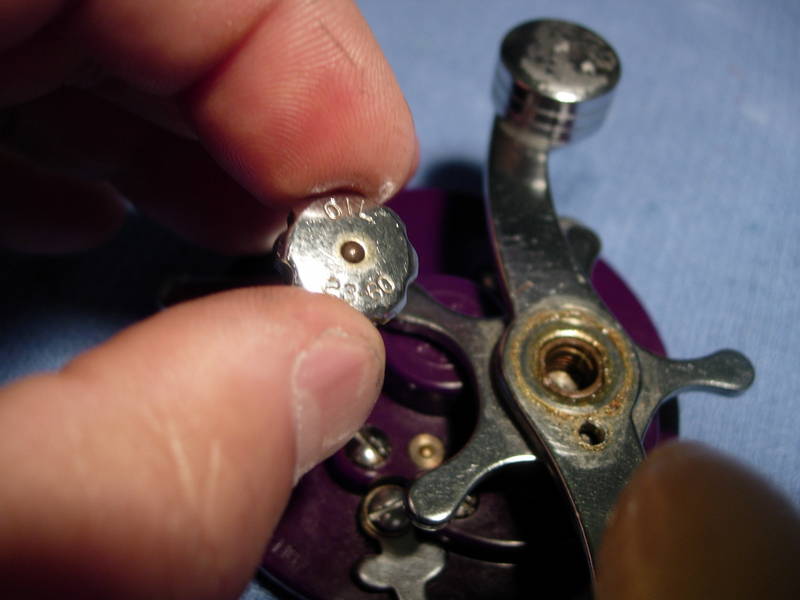

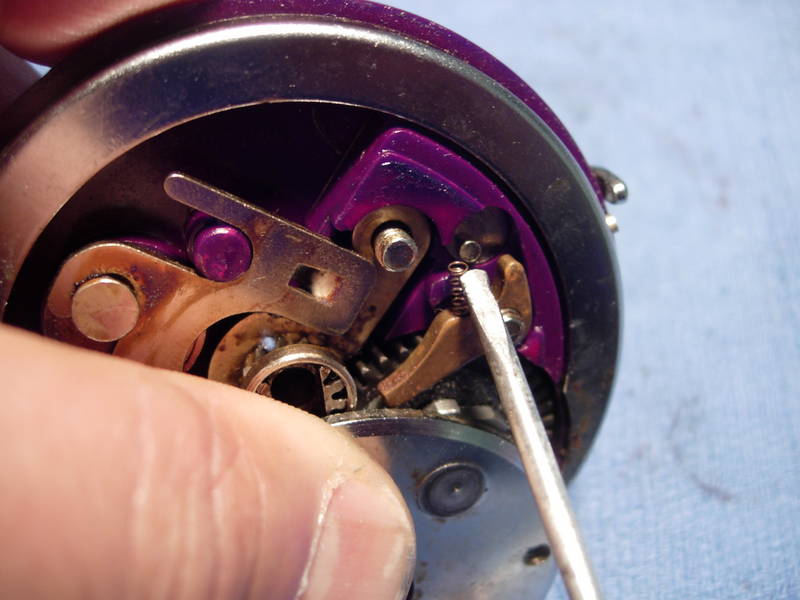

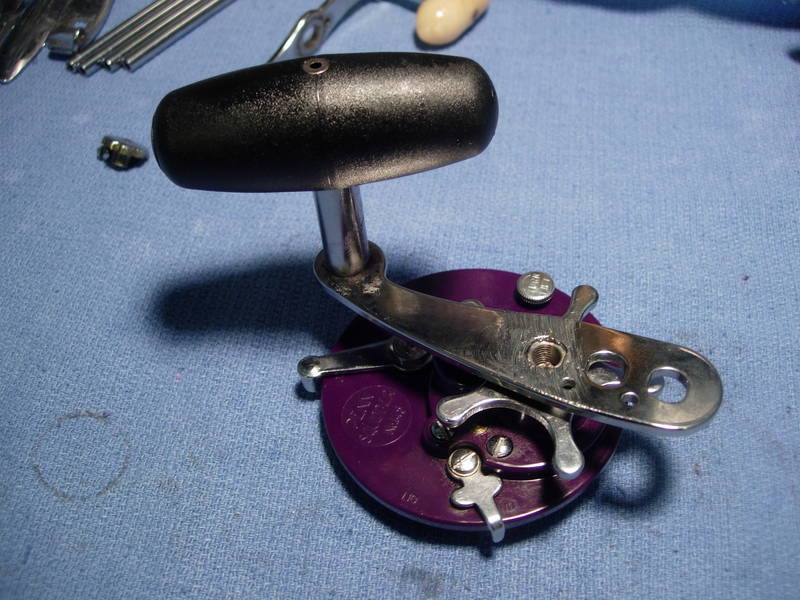

one of the nice features of this reel and the jigmaster is the take apart thumb screw (key #40). turn the screw counterclockwise, lift this spring-loaded screw a little, then turn the entire left side plate counterclockwise and remove the right side plate assembly.

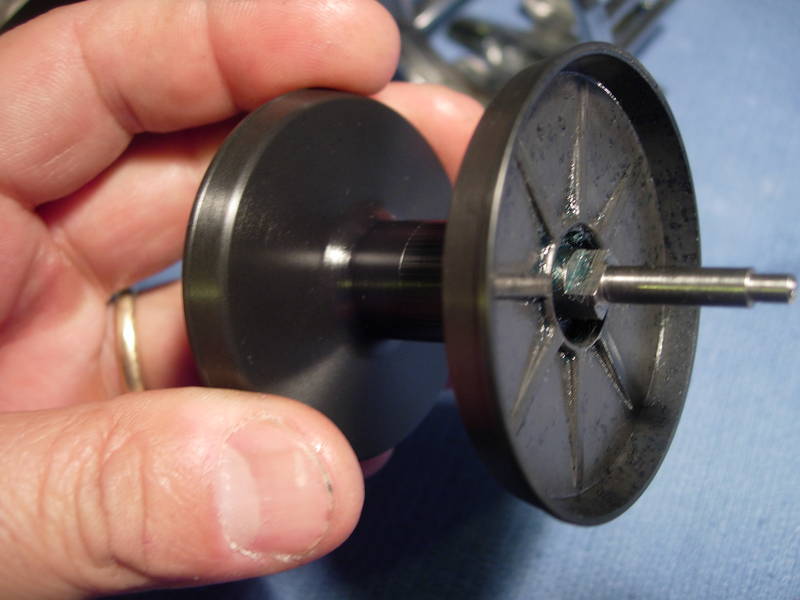

we're now down to three pieces, the frame assembly, spool and right side plate assembly.

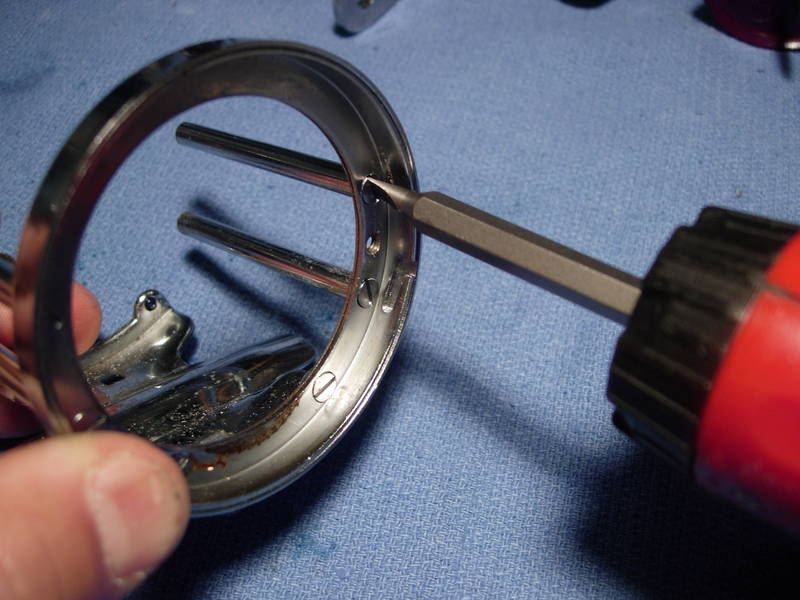

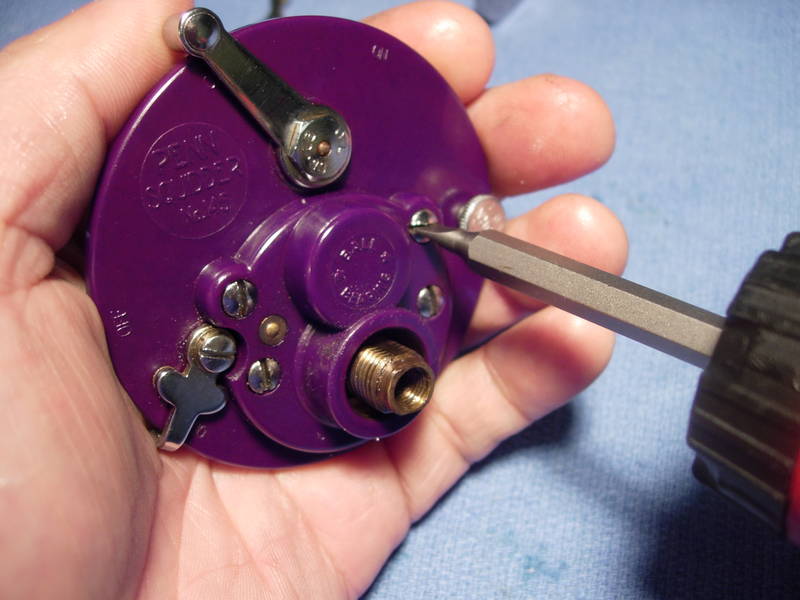

we'll start by removing the left side plate screws (key #'s 32 and 39).

note that the post screws (key #39) are longer than the stand screws (key #32).

grease the screw holes of the new frame posts (key #37) and new stand (key #30) and install them.

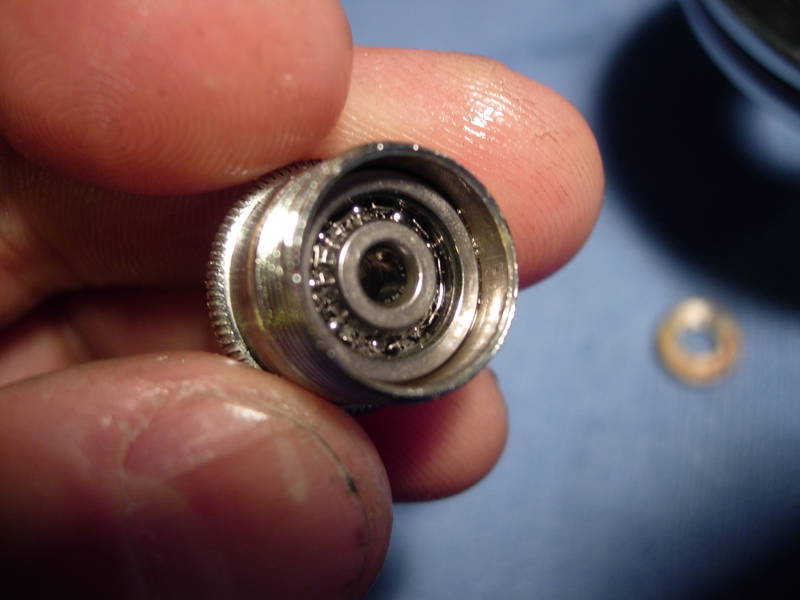

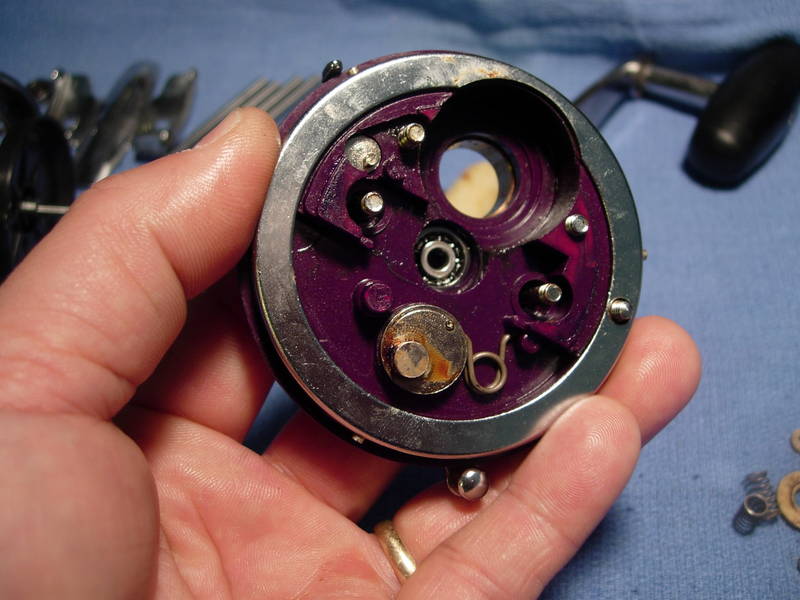

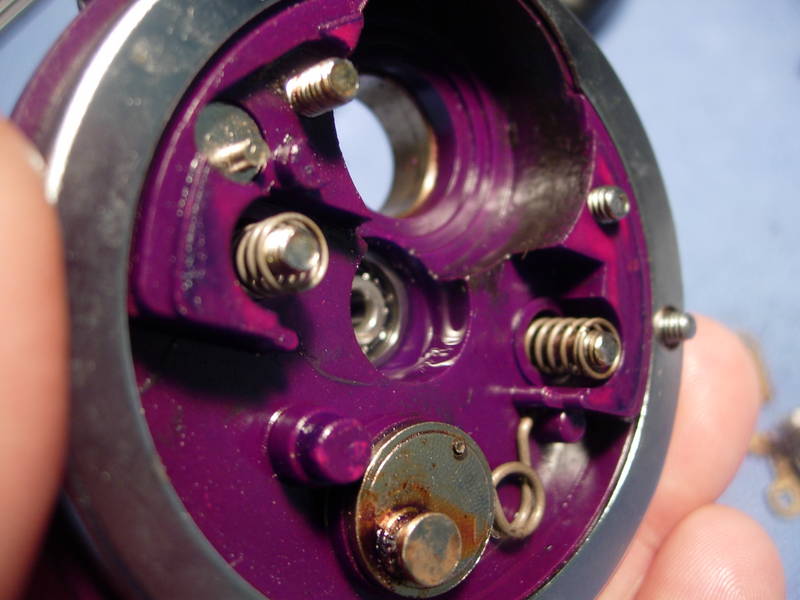

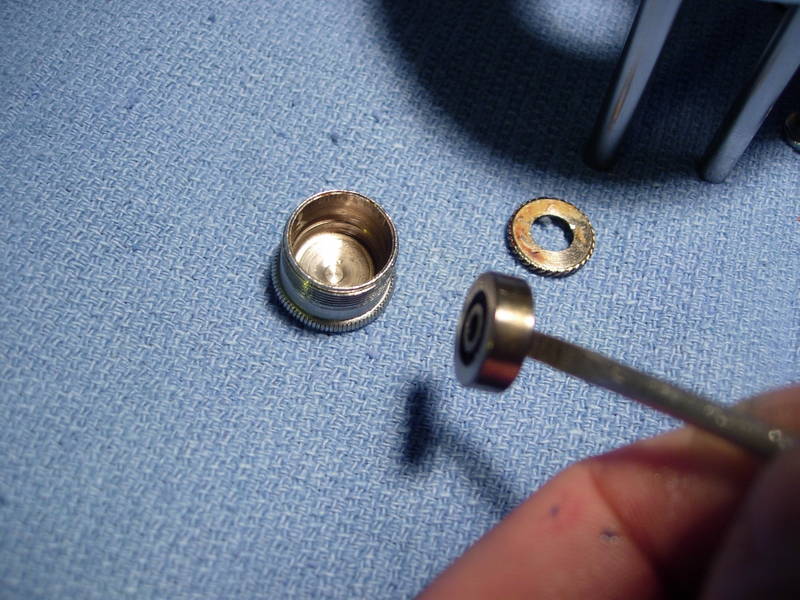

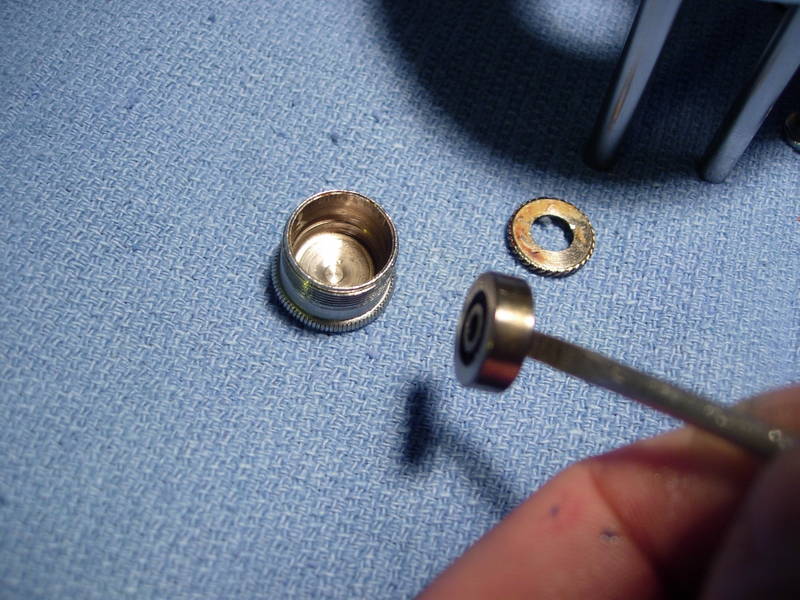

remove the left side bearing (key #40).

pull out the bearing shield (no key #).

the old bearing is toast.

-

Ausfish Bronze Member

-

Ausfish Bronze Member

-

Ausfish Bronze Member

-

Ausfish Bronze Member

Re: penn squidder 140/145/146 rebuild

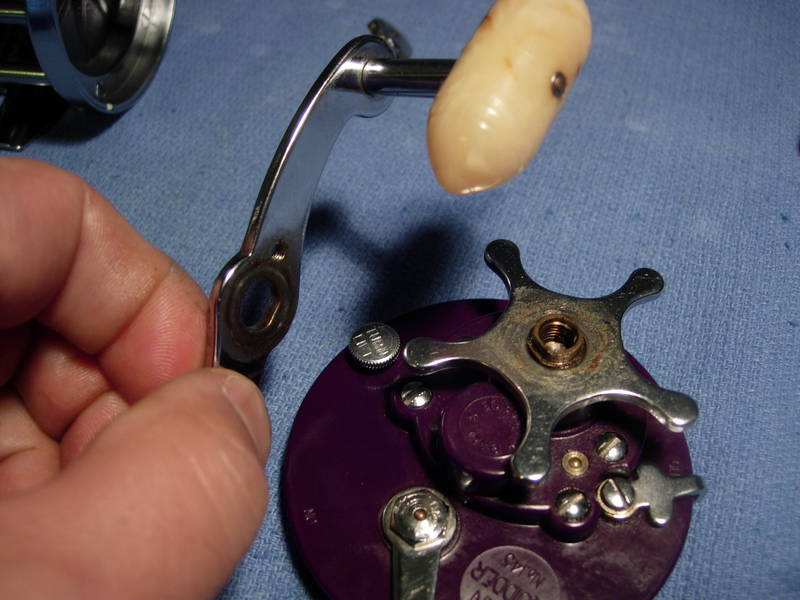

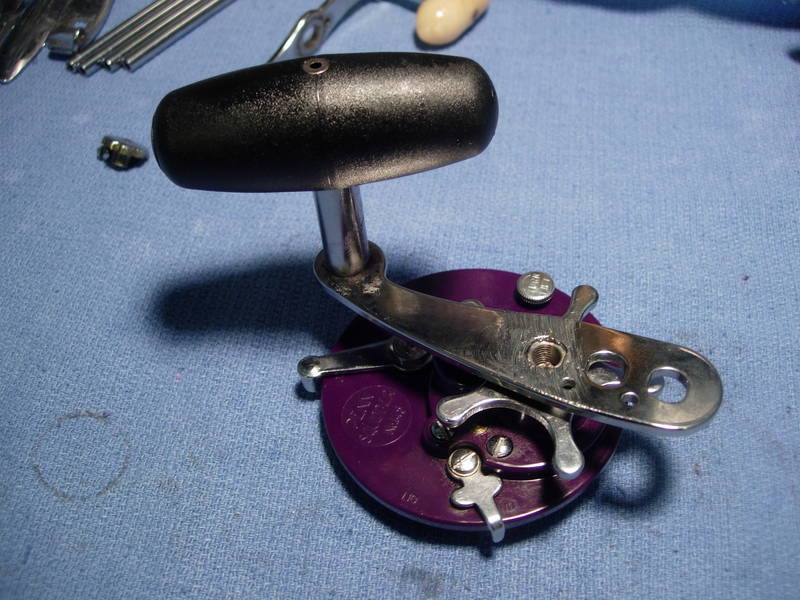

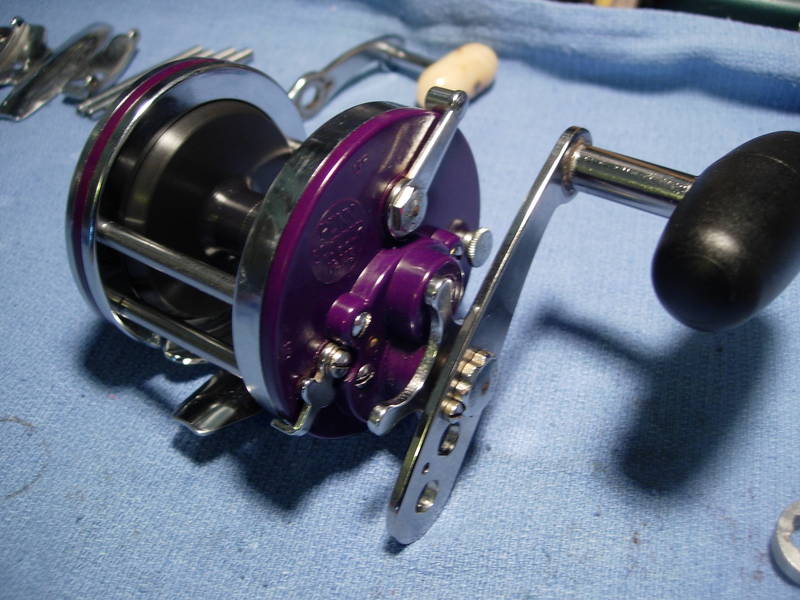

install the upgraded handle (key #24). add a light coat of grease.

install the handle screw (key #23).

install the handle lock screw (key #23A).

press the right side plate assembly down into the right side ring (key #2) until it seats, turn the right side plate assembly clockwise until the take apart thumb screw (key #41) lines up with the threaded screw hole, and turn the thumb screw down until it seats.

congratulations! you're done!

now, for a couple of comments. honestly, there is no way that this upgrade was anywhere near worth the time and expense that was required. but this was never about money, was it. i know one thing for sure. the new owner was a very proud and happy man. personally, i much prefer the balance that the narrowed frame offers. i like my reels "boxed out," having a spool that is as wide as it is tall. with greased carbon fiber drag washers, this reel will deliver a maximum of 12-15 pounds of drag at the top of the spool. the stock brass gear sleeve will start to round off at drag settings in excess of 8 pounds. the stainless steel gear sleeve will easily hold up under 15 pounds of drag. that means that this stainless steel gear sleeve is a worthwhile upgrade ONLY if you are going to fish a 10 pound drag setting with, say, straight 30# mono. that works out well, because the gap between the spool and side plate rings can be so large that the reel will eat 25 pound mono or less. it will also obviously eat spectra. this is an important point. this is not a spectra ready, or spectra worthy, reel.

maintenance of this reel is very simple. the screw holes and drag washers will be good forever. it would be a simple matter to strip off all the line, take the reel apart, flush it out with a full blast of water from a hose, blow out the bearings with compressed air, lube the bearings with more corrosion x, reassemble the reel, spool it up with more 30# mono, reset the drag and set it aside for the next fishing trip. if the bearings foul, you now know how to replace them. other than a fresh water rinse and blow dry, only the bearings are at risk for failure. if you are distance casting, you know that bearing maintenance is critical.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote